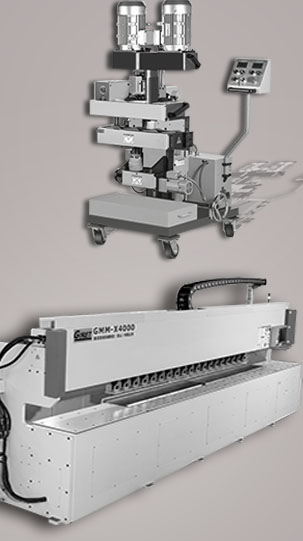

Edge millingmachine, Bevel angle: 0~85degrees, 0~-60degrees, Feed speed:0~2000mm/min

GMM-VS2000 CNC edge milling machine / CNC beveling machine product introduction:

This is an economical CNC edge milling machine and beveling machine product. It has the functions of 0 degree trimming and 0 ~ 85 degree beveling. It can also process U-shaped beveling. Economical CNC edge milling machine is suitable for schools, small factories and laboratories. The processing speed reaches 0 ~ 1500mm / min. it has the function of automatic tool splitting. You can learn the operation of edge milling machine in three minutes.

GMM-VS2000 NC edge milling machine / NC beveling machine power data:

Power supply: AC380V 50Hz (other voltages can be customized)

Total power: 13kw

Operating power: 10kw

Spindle power: 1 * 5.5kw

Touch screen size : 15 inches

Control system: giret-v1 two

GMM-VS2000 NC edge milling machine / NC beveling machine technical data:

Bevel angle: 0 ~ 85 ° (no step adjustment), supporting 90 degrees of step groove

Bevel width: 0 ~ 85 degrees, groove width: 0 ~ 100mm

90 degree step bevel width of upper main shaft. 0 ~ 40mm

Bevel processing speed: 0 ~ 1500mm / min (according to material change)

Thickness of processed bevel plate: 6 ~ 80mm (thicker can be customized)

Length of processed bevel plate: > 150mm (measured length, shorter can be proofed)

Effective bevel processing stroke: 2000mm

Processing material: carbon steel, stainless steel, aluminum alloy and other metal materials

Processing bevel style: V-type / Y-type / U-type / L-type / 0 degree trimming, excessive bevel and highly inclined bevel

Bevel angle accuracy: ± 0.5 degrees

Bevel straightness accuracy: ± 0.5mm

Bevel width accuracy: ± 0.5mm

Operation mode: HMI, human-computer interaction, touch screen control

GMM-VS2000 CNC edge milling machine / CNC beveling machine product features:

1. PLC system control, the system is more stable;

2. HMI human-computer interaction interface, touch screen operation, intelligent beveling machine, which can be operated by ordinary workers;

3. Safer operation: the control panel is low-voltage, and the normal operation is far away from the moving components;

4. The angle of the uphill opening is 0 ~ 85 degrees without step adjustment,

5. The accuracy of groove angle shall reach ± 0.5 degrees;

6. The straightness of processing groove shall reach the accuracy of ± 0.5mm;

7. More environmental protection, no cutting fluid and low noise;

8. Processing data can be stored and called at any time;

9. The diagram of human-computer interaction interface is intuitive;

10. Misoperation prevention system, automatic shielding beyond the limit;

11. The first construction starts the automatic operation groove program;

12. No manual calculation of processing data is required for groove processing, and the system automatically cuts in layers;

13. It supports two language versions, Chinese / English by default, and the language can be customized according to customer requirements;

14. Cold cutting, no oxidation deformation on the surface;

15. Real time monitoring of system input and output status;

GMM-VS2000 CNC edge milling machine application: